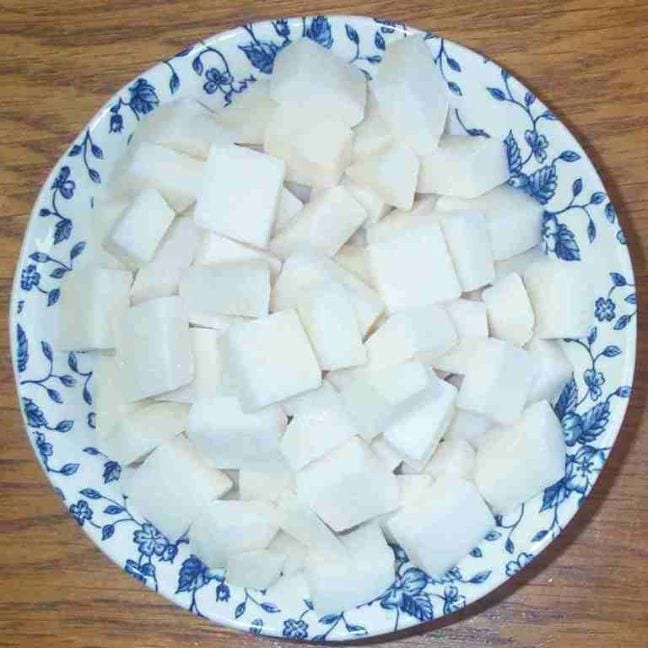

IQF Turnip Diced 20mm

In Season

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Processing

Turnip is delivered fresh to the factory, each load is sampled and assessed for foreign material and physical defects. The load is then cleaned, peeled, cut, blanched, frozen and filled into bulk palletainers. The turnip is sampled and assessed against specification. The palletainers are then labelled and transferred to the cold store, where they are stored at –23°C until required for packing.

Packing

During packing, the turnip is inspected before weighing and filling into blue poly lined cartons. The cartons are Best Before and Production date coded, checkweighed and metal detected, palletised and stretch wrapped before being returned to store at –23°C to await dispatch.