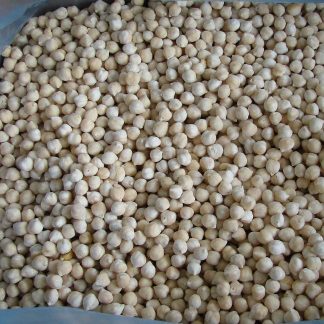

IQF Beans Cannellini

In Season

Processing

Dried Cannellini beans delivered to the factory. Each load is sampled and assessed for foreign material, seed size and physical defects. The load is then soaked for 8 hours, cooked for a time sufficient to reduce the lectin levels to below 400 HAU, frozen and filled into bulk palletainers. The frozen beans are sampled and assessed against this specification. The palletainers are then labelled and transferred to the cold store, where they are stored at –18°C until required for packing.

Packing

During packing, the beans are inspected before weighing and filling into cartons. Cases are printed with product description, production code and Best Before declaration, sealed, palletised and stretch-wrapped before being returned to store at –18°C to await despatch.